January 22, 2025 – The future of circuit board design is poised for a significant shift away from traditional copper-based printed circuit boards (PCBs) as technology demands increasingly higher speeds and bandwidth. Limitations in copper PCBs, particularly in signal integrity at higher frequencies, are becoming more apparent, paving the way for innovative solutions like optical interconnects and photonic integrated circuits.

Industry trends are driving demand for PCBs that are smaller, lighter, more flexible, and deliver significantly higher performance. This push has accelerated with the rise of artificial intelligence and the extreme data processing demands of leading-edge chips like NVIDIA’s Blackwell B200 GPU, which can operate at 720 petaflops and is interconnected with 800 Gbps networking.

A major bottleneck in current high-speed systems lies within the copper interconnects themselves. Copper’s inherent limitations in speed and bandwidth are restricting the flow of data between ultra-fast devices. Since signal transmission in PCBs occurs within the dielectric material, not the copper traces, improving the efficiency of these dielectrics is crucial. However, even advanced low-loss dielectrics offer limited improvement, highlighting the fundamental constraints of copper.

Electro-optical PCBs (EOCBs) emerge as a promising alternative, using light instead of electricity for data transmission. This approach offers superior signal integrity, faster speeds, and greater bandwidth capabilities. Optical interfaces also demonstrate greater energy efficiency at high data rates compared to their electrical counterparts. Furthermore, optical pathways provide enhanced isolation between board layers, ensuring uninterrupted signal transmission and boosting overall performance.

EOCBs strategically integrate both optical and copper pathways; copper handles power distribution and lower-speed data, while optical paths manage high-speed signals. This hybrid approach addresses signal integrity issues common at high frequencies in copper systems, such as skin effect, crosstalk, and skew. Optical systems inherently avoid these problems, offering greater channel density and eliminating the need for signal conditioning and equalization, thus reducing power consumption. This integration also leads to a smaller PCB footprint, potentially reducing surface area by 20% and layer count by up to 50%.

Flexible optical PCBs are also gaining traction, utilizing transparent materials like acrylic or clear epoxy and advanced photolithography and etching techniques to embed optical fibers or waveguides. These waveguides are crucial for modulating and transmitting light signals across the circuit pathways.

High-speed optical interconnects leverage lasers, fiber optics, waveguides, and polarization components to create direct data pathways, minimizing delays and conversions. This ensures high bandwidth and reliable signal transmission. The goal is to achieve three-dimensional optical routing within PCBs using EOCBs and electro-optical transceivers.

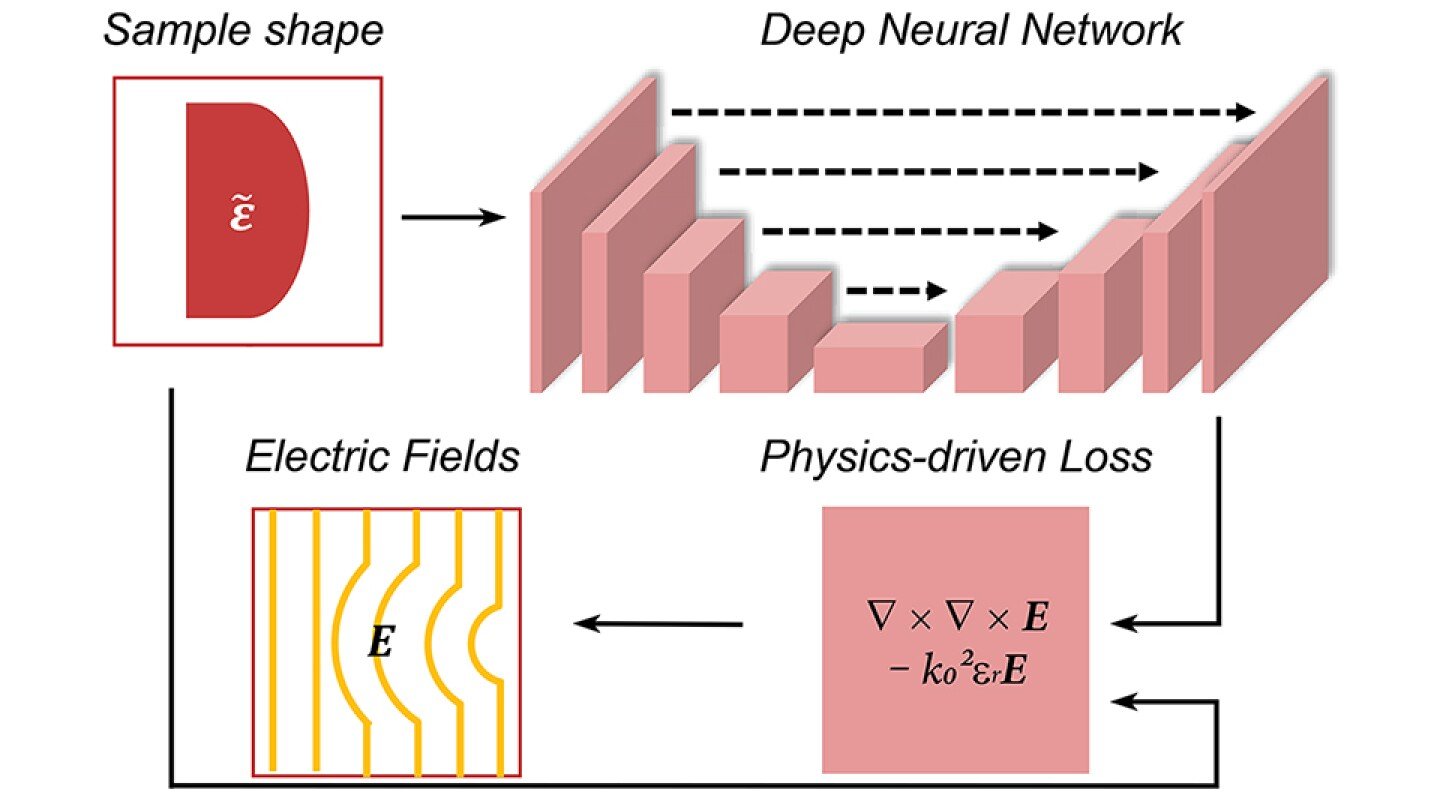

Photonic integrated circuits (PICs) are central to this evolution, acting as microchips containing multiple photonic components that generate, transport, detect, and process light. PIC technology drives the development of next-generation, miniaturized, high-performance devices through advanced features like distributed Bragg reflectors, dielectric waveguides, vertical couplers, and electro-optic modulators. This allows for unprecedented integration densities across applications from communications to sensing.

Onboard optical interconnects can handle significantly higher data rates and channel counts compared to electrical interconnections while also being impervious to electromagnetic interference (EMI). This EMI immunity makes them particularly suitable for mixed-signal systems like data acquisition and sensitive sensor applications.

Manufacturing optical PCBs requires careful consideration of waveguide fabrication, ensuring low signal attenuation and a reliable process compatible with existing PCB industry standards. This compatibility extends to assembly processes, needing coupling elements for optical signal input and output that can be automatically mounted using standard pick-and-place machines, ideally without requiring active alignment. Structured polymer foils are being explored to facilitate this integration.

EOCB construction involves laminating low-cost glass sheets with conventional materials like FR-4. Glass can be used as a core layer or as a photonic interposer carrying PICs and electronic components. Copper plating is applicable to both glass and organic materials, maintaining compatibility with standard PCB processing, though high-precision assembly is necessary.

Currently, challenges remain in connecting transceivers to the glass layer within EOCBs, specifically in routing photonic signals. Two main techniques are under development: using a periscope from the top or a small mirror from the bottom of the EOCB. However, industry-wide standards are yet to be established for these techniques.

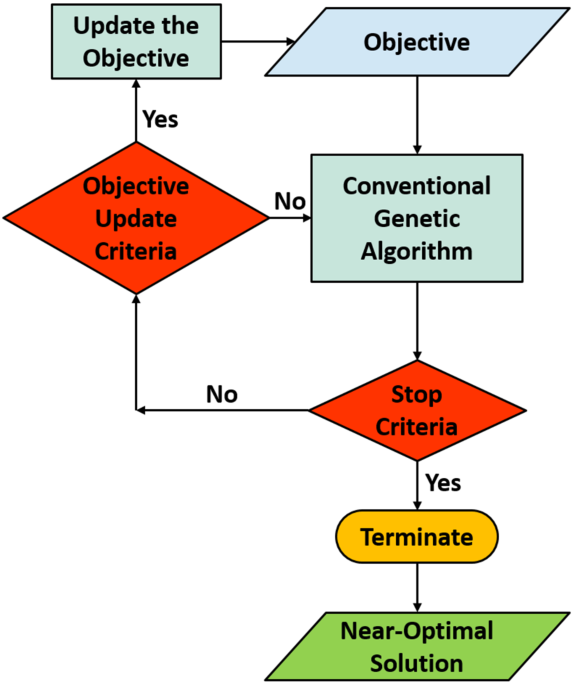

Developing EOCBs requires addressing design challenges across electrical (RF and electrical signal path optimization), optical (signal optimization, collimation, optomechanical system design), and thermal (heat source management and sink integration) domains.

Fabricating waveguides within the glass layer of EOCBs is a critical technology, analogous to printing circuits on standard PCBs. Waveguides can be designed for single-mode (SM) or multi-mode (MM) transmission, with single-mode being favored in silicon photonics and multi-mode in datacom. Waveguides in glass can be created using lasers or ion exchange processes, with ion exchange offering the advantage of parallel processing.

Looking ahead, EOCBs are expected to be crucial for future data processing needs, driven by the growing demands of AI and increasing data usage. Integrated optical connections will be vital at all levels, from chips to full panels. Waveguides made using ion-exchange processes in affordable display glass, laminated with conventional PCB materials, present a promising pathway to meet these needs and integrate optical conductors alongside traditional electrical routing.

Source link