A new microfabrication technology is bridging the gap between intricate optical designs and large-scale manufacturing of optics for wafers. This innovation combines additive microfabrication with step-and-repeat nanoimprint lithography, paving the way for mass production of advanced micro-optical components.

The demand for sophisticated optical sensors in smartphones, tablets, wearables, and other mobile devices is surging, driving the need for cost-effective miniaturization of optical components. Wafer-level optics manufacturing, which utilizes semiconductor-style processes, offers a promising solution.

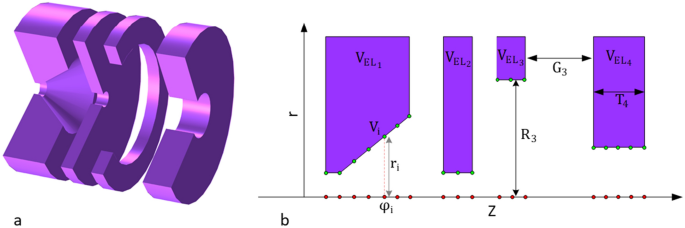

Step-and-repeat nanoimprint lithography (S&R NIL) now enables the scaling of highly detailed optical structures, initially designed at the die level, to full 300mm wafers. This is achieved by replicating a master mold multiple times across a substrate, creating master templates that maintain the fidelity of the original design. This S&R master then facilitates the production of working stamps for subsequent wafer-level manufacturing. This approach is significantly faster and less costly than traditional methods, enabling the mass production of sophisticated optical designs previously limited to niche applications.

Key to creating these initial master molds is two-photon grayscale lithography (2GL), a high-precision 3D printing technology. 2GL allows for the fabrication of complex micro-optical elements with exceptional shape accuracy and extremely smooth surfaces, surpassing traditional methods like diamond turning or electron-beam lithography. It offers rapid design iterations and cost-effective microfabrication of 2.5-dimensional structures.

By combining the design freedom and precision of 2GL with the efficient replication of UV-nanoimprint lithography (UV-NIL) and S&R mastering, a complete manufacturing chain is established. This process begins with creating a master using 2GL, scaling it to the wafer level through S&R mastering, and finally enabling high-volume wafer-level production using NIL.

The S&R mastering process ensures high precision with alignment within 250 nanometers and comprehensive process control, maintaining an optimal environment throughout dispensing, imprint, curing, and demolding. Working stamps, replicated from the S&R master, are used for the final imprint, minimizing wear on the expensive master and allowing for quick and cost-effective replacement of defective stamps during mass production.

While polymer shrinkage during replication can cause slight dimensional changes, these are predictable and can be compensated for in the master design, particularly facilitated by the flexibility of 2GL. The 2GL method allows for rapid prototyping and direct testing of designs on glass substrates, enabling early design validation and quicker iteration cycles. This combined approach significantly reduces the time required to bring innovative optical designs from concept to mass market, not only for advanced micro-optics but also for other 2.5D structures like sensor components in microfluidic chips. Ultimately, this technology breakthrough overcomes previous limitations in micro-optics manufacturing, paving the way for improved performance and new applications in consumer electronics and beyond.