Researchers have developed a novel artificial intelligence framework to significantly accelerate the design of advanced materials with specific optical properties. This innovative system combines several neural networks to rapidly predict and optimize the characteristics of microstructured materials, overcoming the limitations of traditional simulation methods which can be computationally intensive and time-consuming.

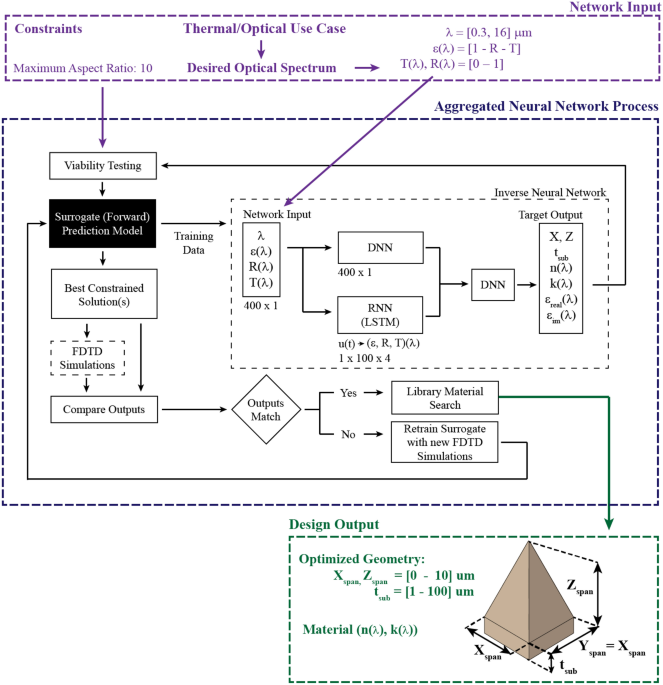

The new framework utilizes a four-stage process. It begins with data generated from Finite-Difference Time-Domain (FDTD) simulations, a method for precisely modeling light-matter interactions. This data is then used to train a “surrogate” neural network, which acts as a fast predictor of optical properties for various materials. This surrogate network rapidly assesses a wide range of materials, generating predictions that then train a second “inverse” neural network.

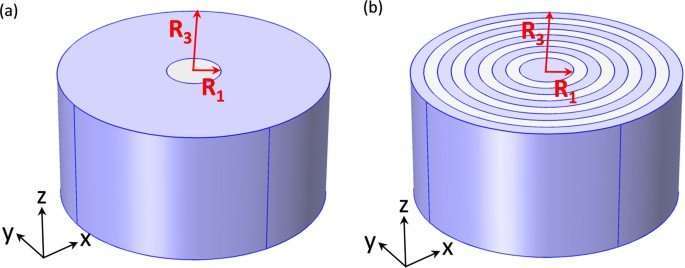

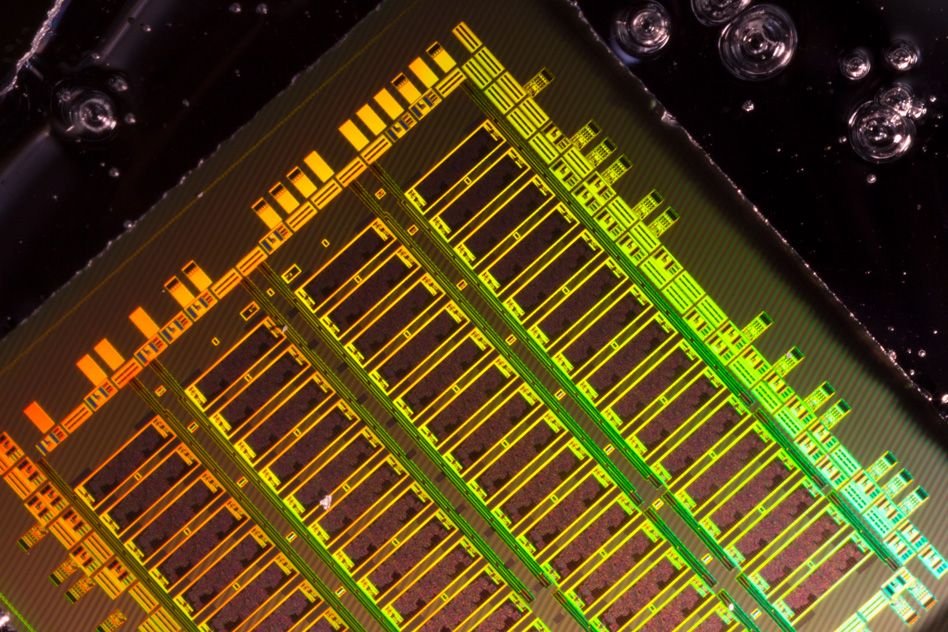

The inverse network is the core of the design tool. It takes a desired optical spectrum – essentially the blueprint of how light should interact with the material in terms of wavelength, emissivity, reflectivity, and transmissivity – as input. It then predicts the optimal physical structure of the material, including the dimensions of micropyramids on its surface and the material composition (specifically, the complex refractive index).

A crucial “post-processing” module is incorporated to ensure the practicality of the design. This module interprets the output of the inverse network and applies real-world constraints, such as limitations on the aspect ratio of the microstructure (how tall it is compared to its width) to ensure the designs are manufacturable. If the initial solution doesn’t meet these constraints, the system automatically adjusts the design to find viable alternatives. The adjusted solutions are then re-evaluated using both FDTD and the surrogate model to ensure accuracy. The system is designed to iteratively refine its predictions; if discrepancies are found between the desired optical properties and the achieved ones, or between the surrogate model’s prediction and the more accurate FDTD simulations, the surrogate network can be retrained with new data to improve its future performance.

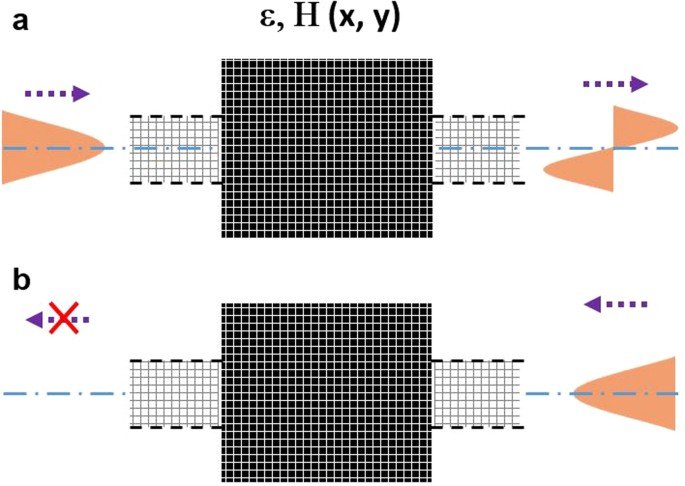

The researchers emphasize the effectiveness of the surrogate neural network. They have developed two versions: a deep neural network (DNN) and a convolutional deep neural network (CDNN). Both are trained on data from FDTD simulations of micropyramid structures. The DNN directly processes geometric and material inputs to predict optical properties, demonstrating rapid prediction speeds and good accuracy, even when dealing with materials not explicitly included in its training data. The CDNN takes a different approach, analyzing a visual representation of the material structure, mimicking how an FDTD solver works by considering material properties across a discretized mesh. This image-based method proves to be even more accurate in predicting properties for new materials, especially when limited training data is available.

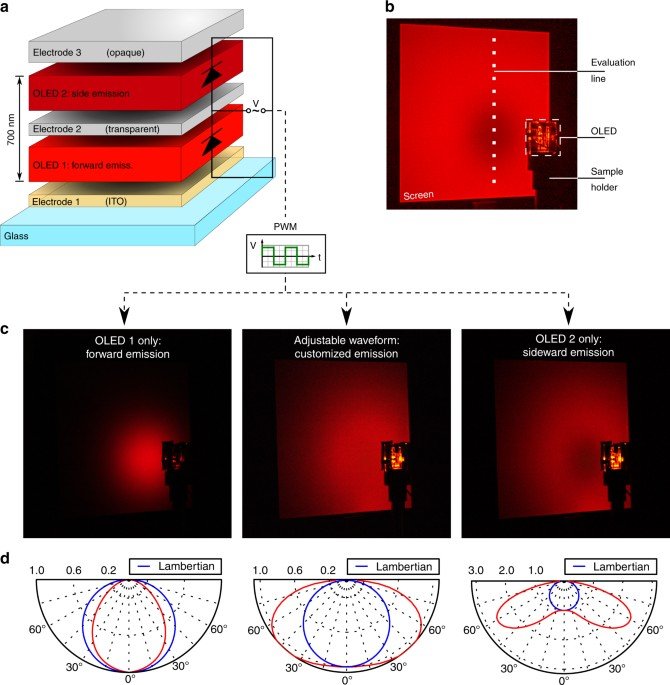

The inverse neural network, built upon the speed of the surrogate network, is designed to solve the “inverse problem” – determining the material and structure needed to achieve a specific optical response. It analyzes the full spectral distribution of desired optical properties and outputs the corresponding geometric parameters and material properties. Tests using target spectra for ideal heating, cooling, and unity emissivity demonstrate the network’s capability to generate functional designs, even for complex and potentially physically challenging target optical responses.

While the inverse network excels at design, it doesn’t inherently incorporate manufacturing constraints. The post-processing module addresses this by allowing users to set limitations, such as maximum aspect ratios, which are crucial for real-world fabrication. This module refines the initial network output, searching for alternative, manufacturable designs that still closely match the desired optical performance. This iterative process involves adjusting the geometry, re-simulating with the surrogate model, and verifying the best solutions with FDTD, ensuring the final designs are both practical and effective.

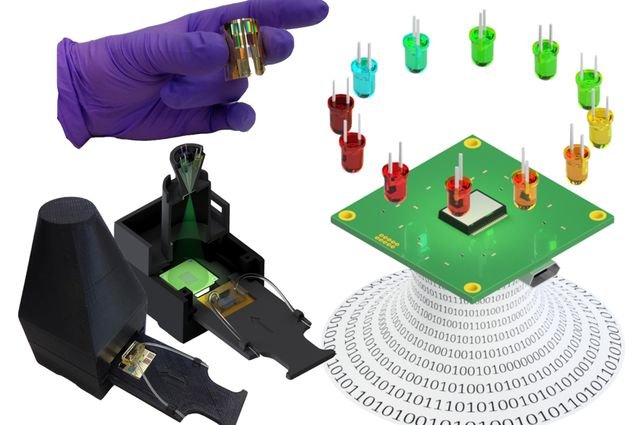

The aggregated neural network system is designed to be self-improving. By continuously comparing its predictions with accurate simulations and real-world constraints, and incorporating new data, the system learns and refines its design capabilities over time. This technology holds significant promise for accelerating innovation in various fields, including energy management, thermal control, and advanced optical devices, by enabling rapid and efficient design of metamaterials tailored to specific needs.