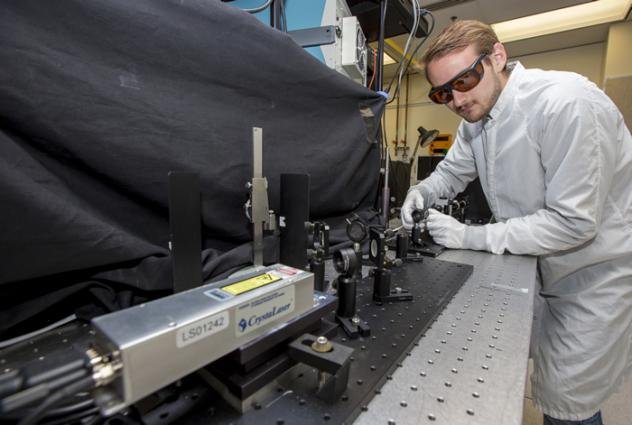

Dylan Beckman, a 20-year-old optical engineering student from the University of Rochester, is contributing to the National Ignition Facility (NIF) this summer as a summer scholar. Beckman is designing new methods for transporting ultraviolet light via optical fiber cables from the Target Chamber to external diagnostic instruments at NIF. His designs have the potential to be implemented across all 192 of NIF’s laser beams.

Beckman’s fascination with lasers began during a tour of the University of Rochester’s optical engineering building, leading him to switch his major from chemical engineering to optical engineering. His current work at NIF involves creating a more complex optical lens system to ease the load on optical fibers used to measure laser power. Mentors Abe Handler and Leyden Chang from the NIF Laser Diagnostics Group, along with Mike Messerly, Fiber Laser Group leader, have praised Beckman’s contributions. Messerly noted that Beckman’s designs are expected to simplify operations and improve efficiency at NIF.

Currently, NIF measures power in only a quarter of its beamlines, relying on computer modeling for the remaining beams. Beckman is tasked with developing a system that could be deployed across all 192 beamlines, enhancing measurement accuracy and increasing confidence in laser performance for scientists and engineers. Handler explained that this upgrade is crucial for the future of NIF, as improved beamline information enables better system characterization and higher energy output.

Beckman is developing physical prototypes of his system, aiming for a cost-effective design. Handler emphasized the significance of this project for the entire NIF facility and its users. While fiber optic cables are common in telecommunications, NIF requires specialized fibers capable of transmitting ultraviolet light and withstanding high-radiation environments. Messerly highlighted the challenges of using off-the-shelf solutions for NIF’s unique needs but noted that Beckman’s designs simplify the requirements for these custom fibers, potentially facilitating wider implementation across the facility.

Handler acknowledged the complexity of NIF, especially for newcomers, but commended Beckman for his rapid skill acquisition and proactive approach. Beckman expressed his awe at the scale and complexity of NIF, describing it as a “giant well-oiled machine.” He is enthusiastic about contributing to such a large-scale project and hopes his system will be integrated into NIF, leaving a lasting impact on the world’s largest laser facility.

Leave a Reply