Scientists in Israel have developed a novel and cost-effective method for creating diffractive optical elements (DOEs), which are crucial components for shaping light in advanced optical systems. Unlike traditional lenses, DOEs can manipulate light in complex ways but typically require expensive and intricate manufacturing. Researchers at The Technion achieved this breakthrough by combining 3D printing with a liquid immersion technique using water and glycerol, a common food additive.

The two-step process begins with 3D printing the desired shape of the optical element, such as a phase mask. This 3D-printed mold is then used to cast a transparent polymer DOE element. The key innovation lies in immersing this element within a small chamber filled with a mixture of water and glycerol. By adjusting the ratio of water to glycerol, scientists can precisely fine-tune the optical properties of the DOE.

This liquid immersion approach offers several advantages. It allows for the creation of DOEs with larger features – at the scale of tens of microns instead of tens of nanometers – meaning less precise and thus more affordable 3D printers can be used. Professor Yoav Shechtman, a biomedical engineer at the Technion, highlighted that modern additive-manufacturing (3D printing) technology was essential for enabling the creation of these non-standard optical elements efficiently. His team, including graduate student Reut Orange-Kedem, discovered that immersing the DOE in a liquid with a refractive index similar to the solid element effectively increases the element’s axial size and tolerance for manufacturing errors.

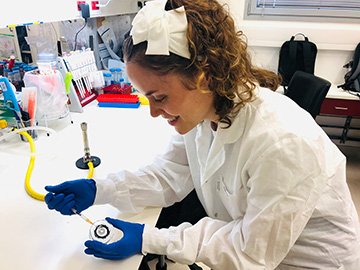

Following the casting of the polymer element, it is bonded to a silica substrate and placed within a specially designed chamber. After removing any air bubbles, the chamber is filled with the water-glycerol mixture. The ability to easily switch and adjust the liquid mixture allows for adaptable optical performance. The researchers successfully tested their liquid-immersion DOE in 3D single-molecule localization microscopy of fluorescently labeled cells.

The reusability of the 3D-printed mold and the potential to create multiple designs from a single mold make this technique attractive for optics manufacturers. Professor Shechtman suggests that while applicable to various transparent optical elements, the method is particularly impactful for creating unconventional optical elements like DOEs and those with specialized geometries. The team hopes to see broad adoption of this technique in both academic and industrial settings and aims to further explore more complex optical designs and integration into biomedical imaging systems.

Leave a Reply