University of Michigan researchers have developed a new algorithm, named OptoGPT, that leverages transformer neural networks, similar to those powering large language models, to revolutionize the design of optical components. This innovation aims to streamline the creation of optical multilayer film structures, which are essential for technologies like solar cells, smart windows, and telescopes.

OptoGPT is designed to work backward, starting with desired optical properties to determine the precise material structure needed to achieve them. These multilayer films, composed of stacked thin layers of different materials, can be optimized for various functions such as maximizing light absorption in solar cells or reflection in telescopes. They are also crucial in advanced semiconductor manufacturing and in smart windows that adapt their transparency and reflectivity to regulate building temperature.

A significant advantage of OptoGPT is its speed and efficiency. It can generate designs for multilayer film structures in just 0.1 seconds, and these designs require an average of six fewer layers compared to those produced by previous methods, simplifying the manufacturing process.

L. Jay Guo, a professor of electrical and computer engineering at the University of Michigan, and the study’s corresponding author, emphasized the complexity of traditional design processes, noting that OptoGPT automates this challenging task.

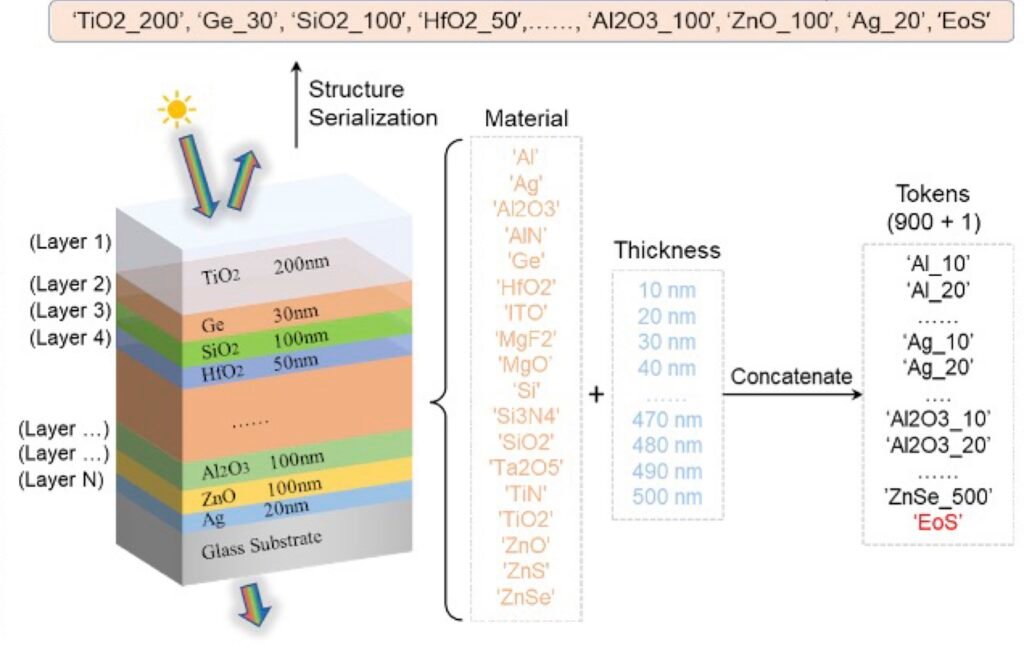

The research team adapted a transformer architecture, the machine learning framework behind models like ChatGPT, for optical design. They essentially translated materials and their thicknesses into "words" recognizable by the model. By identifying correlations between these "words," OptoGPT predicts the optimal "phrase," or in this context, a design for a multilayer film structure that meets specific optical property requirements.

To validate OptoGPT’s performance, researchers compared its designs against a dataset of 1000 known structures. The difference between OptoGPT’s designs and the validation set was minimal, at only 2.58%, demonstrating high accuracy. Further fine-tuning of the designs improved accuracy to 1.92%.

Researchers also explored the inner workings of OptoGPT, mapping its decision-making processes to understand how it associates materials and thicknesses. This analysis confirmed the algorithm’s alignment with optical principles, as materials clustered logically by type and exhibited expected behaviors at minute thicknesses.

OptoGPT represents a significant advancement in inverse design algorithms, offering broader applicability compared to previous task-specific approaches. This new tool empowers researchers and engineers to efficiently design optical multilayer film structures for a wide range of applications. The research findings have been published in the journal Opto-Electronic Advances.

Leave a Reply